AREAS OF APPLICATION

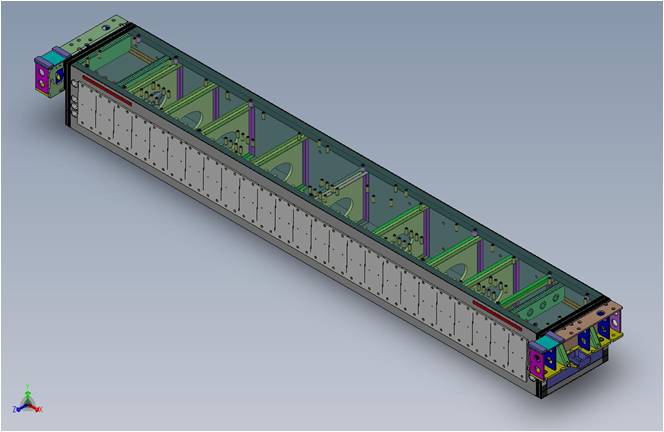

In mechanical engineering, our lightweight rods are inserted as stiffening girders in CFRP sandwich panels, which are then assembled into beam structures, for example as gantries for processing machines.

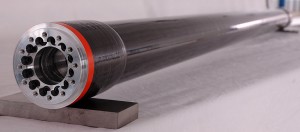

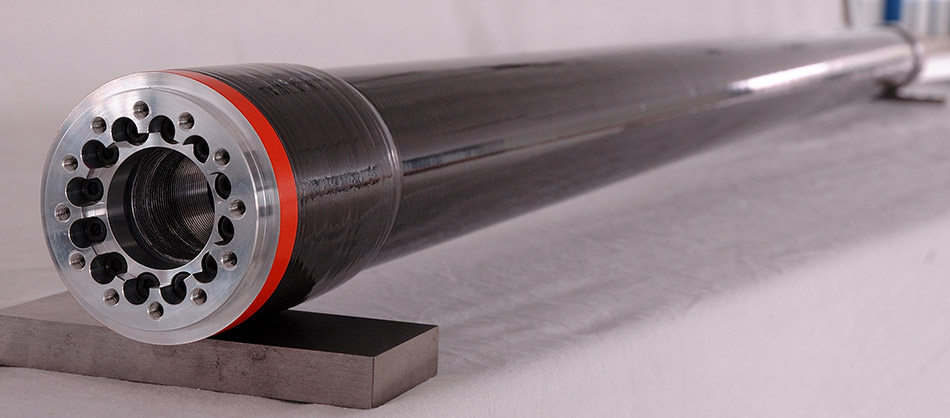

CFRP sandwich rods are also integrated directly into machines. Here, our highly fatigue-resistant interface elements in the form of a conical clamping mechanisms have proven particularly effective. A typical application is as coupling rods for fatigue test rigs.

Hybrid elements consisting of CFRP parts and metal parts are used to selectively reinforce load directions of an otherwise conventional metal structure.

The high weight-related stiffness of CFRP solutions in mechanical engineering and the associated high natural frequency mean that machine parts can be accelerated more strongly and controlled more dynamically. This leads to significantly higher speeds with the same accuracy.

SPECIAL PROPERTIES

TYPICAL AREAS OF APPLICATION

PROJECT EXAMPLES

Coupling rods in fatigue test stands connect the driving hydraulics with the receptacles for the test objects. The coupling rods are loaded with large, alternating loads in rapid succession over their entire service life. To maintain the dynamics of the drive, the coupling rods must be light, stiff and themselves very fatigue-resistant. CFRP sandwich rods with our proven clamping-based interface elements meet all these requirements excellently.

Hybrid profiles combine the outstanding properties of CFRP, high weight-related stiffness and strength, with the proven processing and machining of metals. This results in finished parts and hybrid semi-finished products that can be further processed like metals, e.g. by laser welding. In this way, the advantages of CFRP can be used in machines in a targeted and cost-efficient manner.

The combination of lightweight CFRP rods with CFRP sandwich plates produces beam structures which are used as motion units in processing machines. Due to the high weight-related stiffness and the associated high natural frequency, the moving axis can be moved much more dynamically. This leads to significantly higher machining speeds while maintaining the same manufacturing accuracy.

The personnel-carrying cage of this CableRobot is made of CFRP sandwich bars. As a result, the mass of the cage is low. At the same time, people on board are protected by the high strength reserves of the material. The rods are connected at the nodes by very reliable interface elements based on cone clamping.